aberfan - geotechnical summary

The series of spoil piles, of which the number 7 tip failed, were the biggest feature on the landscape, reaching 220 feet above the surrounding hillside. The tip material was dominantly ground shale fragments, mostly sand to fine sand sized, but with 20 % finer than 2 micrometers. The high percentage of fines reduces the shear strength of this material (Taylor, 1986, fig. 4), but more importantly it reduces permeability and therefore impedes the dissipation of excess pore pressure (and hence impeded consolidation). This slow consolidation favors liquefaction (Bishop, 1973, p. 366).

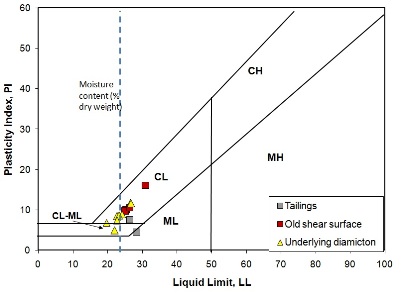

Mineralogically, the fine fraction was illite and kaolinite with no expandable clays. This material seemed relatively innocuous. It did not pose the sliding hazard associated with expandable clays, and it had an angle of internal friction ranging between 33 and 39 degrees (Bishop et al., 1969, Appendix 3).

It was, however, loose. Dry unit weight was 100 lb/ft3, compared with a maximum value of 121 lb/ft3. (See Table of Geotechnical Parameters). The usual specification for compaction of embankments in the UK at this time was 95% of the maximum, or 115 lb/ft3 in this case. Thus the spoil pile was loose and should have been compacted in lifts as it was being constructed rather than simply having the material “tipped” onto the top of the cone of debris.

Also note that the water content of the waste material was, on average, 24 % of dry weight compared with a liquid limit of 26.5 %. Thus a small addition of water, for example from springs beneath the waste pile, would lead to failure. (see also Varying definitions of water content in geology and engineering)

ABERFAN REFERENCES

BUY BOOKS ON ABERFAN AND OTHER MINE DISASTERS